إن اختيار بين الألواح الخشبية أو الفولاذية للسقالات له تأثير كبير على نتائج العمل الإنشائي. يفضل معظم المقاولين الخشب لأنه أقل تكلفة وسهل الاستخدام. هذه الألواح خفيفة بما يكفي لتحملها العمال طوال اليوم، ولذلك ما زالت المهام الصغيرة أو التركيبات المؤقتة تعتمد على الألواح الخشبية. ولكن هناك عيبًا؛ إذ يميل الخشب إلى التشويه إذا ترك في الخارج لفترة طويلة أو يتعفن عند التعرض للرطوبة، ولذلك تصبح الفحوصات الدورية وتجليخ الأسطح من ضمن عمليات الصيانة الروتينية. أما الألواح الفولاذية فلها قصة مختلفة تمامًا. هذه الألواح تدوم لفترة أطول بكثير وتصمد أمام أي ظروف جوية دون مشكلة. لا تنكسر الألواح الفولاذية تحت ضغط المواد الثقيلة، ولذلك تعتمد عليها عادة المواقع التجارية الكبيرة والمشاريع البنية التحتية. بالتأكيد هي أعلى تكلفة في البداية، ولكن لا أحد يرغب باستبدال الألواح كل بضعة أشهر خلال موسم الأمطار.

تشير الأبحاث إلى أن الألواح الفولاذية للسقالات تدوم عادةً لفترة أطول بكثير من الألواح الخشبية، كما تتطلب صيانة أقل بمرور الوقت. بالطبع، قد تكون الخشب أرخص في البداية، لكن كل تلك الاستبدالات والإصلاحات المتكررة تضيف تكاليف سريعة عند النظر في التكلفة الإجمالية عبر مشاريع متعددة. علاوة على ذلك، فإن الألواح الفولاذية لا تتآكل كما يفعل الخشب. هذه الألواح المعدنية تتحمل ظروف الطقس بشكل أفضل، وتقاوم الضرر الناتج عن الأمطار والتعرض لأشعة الشمس، ولا تتعفن بغض النظر عن الظروف الجوية التي تتعرض لها في الموقع. يشير الخبراء في الصناعة إلى أن اختيار بين الخشب والفولاذ يعتمد حقًا على ما يناسب كل موقع عمل على حدة. يحتاج المقاولون إلى مقارنة الإنفاق الأولي مقابل التوفير على المدى الطويل، بالإضافة إلى التفكير في مدى صعوبة التعامل مع كل مادة أثناء عملية البناء.

يُحدث معرفة معنى سعة التحميل فرقاً كبيراً عند اختيار ألواح السقالات لمشروع معين. ببساطة، تُشير سعة التحميل إلى كمية الوزن الذي يمكن أن تتحمله السقالة قبل أن تبدأ بالانهيار. ولا تعتبر المتابعة لتلك الإرشادات الصناعية مجرد إجراء ورقي فقط، بل هي ضرورية لضمان سلامة جميع العمال في الموقع. عندما يختار العمال ألواحاً لا تفي المواصفات المطلوبة لسعة التحميل، يمكن أن تحدث الحوادث بسرعة. لقد شهدنا حالات حيث أدت استخدام الألواح غير المناسبة إلى انهيارات أثناء أعمال البناء، مما عرّض حياة الناس للخطر وتسببت في تأخيرات كبيرة. خذ على سبيل المثال البناء السكني مقابل البناء التجاري. تحتاج معظم مشاريع تحسين المنازل إلى ألواح مصنّفة لتحمل حمولة تبلغ حوالي 25 رطلاً لكل قدم مربع (psf)، لكن المواقع التجارية الكبيرة تتطلب عادةً ألواحاً تتحمل ما يقارب 50 رطلاً لكل قدم مربع أو حتى أكثر اعتماداً على نوع المواد التي تُستخدم يومياً.

تتطلب أنواع مختلفة من مشاريع البناء مستويات دعم هيكلية متفاوتة. عند العمل في المواقع التجارية، يكون هناك عادةً وزن أكبر بكثير بسبب الآلات الثقيلة والعديد من العمال الذين يتحركون في نفس الوقت. هذا يعني أننا نحتاج إلى تركيبات سقالات أقوى لهذه المشاريع. أما بالنسبة للمنازل، فإن معظم أعمال الصيانة أو التجديدات السكنية تتطلب فقط سقالات أساسية، حيث لا تشمل هذه الأعمال عادةً أحمالاً شديدة. ويمكن أن يؤدي ارتكاب خطأ في التقدير إلى مشاكل جدية في المستقبل. لقد شهدنا العديد من الحالات الواقعية التي أدت فيها حسابات الأحمال غير الصحيحة إلى انهيار المباني، ما تسبب في إصابات بشرية في بعض الأحيان وأدى حتماً إلى تعقيدات كبيرة للشركات التي اضطُرَّت لاحقاً إلى التعامل مع الدعاوى القضائية. أما بالنسبة للمقاولين الذين يخصصون الوقت الكافي لتقييم احتياجاتهم بدقة من حيث توزيع الوزن المتوقع وعدد أفراد الطاقم الذين سيصلون إلى المناطق المختلفة، فإنهم يتجنبون هذه المشكلات تماماً، ويحافظون على سير العمليات بسلاسة منذ اليوم الأول.

اتباع قواعد منصة العمل المؤقتة التابعة لـ OSHA يُحدث فرقاً كبيراً في الحفاظ على سلامة العمال في مواقع البناء. لقد وضعت إدارة السلامة والصحة المهنية متطلبات واضحة لبناء منصات العمل المؤقتة وصيانتها، مثل التأكد من تركيبها بشكل صحيح وإجراء الفحوصات اللازمة بانتظام لتجنب الحوادث. كما أن توزيع الوزن يلعب دوراً كبيراً أيضاً، لأنه إذا لم تُوزَّع المواد بشكل صحيح على سطح المنصة، فإن خطر الانهيار يكون حقيقياً. الشركات الإنشائية التي تلتزم بهذه المعايير تقلل من المواقف الخطرة التي تشمل السقوط من الأماكن المرتفعة أو انهيار الهياكل، وهو أمر يدعمه خبراء السلامة دون أي تردد. نظرة على الأرقام تُظهر أن الأماكن التي تطبّق إرشادات OSHA شهدت انخفاضاً في معدلات الحوادث المتعلقة بالمنصات بنسبة تزيد عن سبعين بالمائة مقارنة بالمناطق التي لا يتم فيها الالتزام بهذه القواعد بشكل دائم.

تلعب ميزات منع الانزلاق على ألواح السقالات دوراً كبيراً لأنها تساعد في منع إصابة العمال نتيجة الانزلاق والوقوع. تأتي معظم السقالات هذه الأيام بأنواع مختلفة من التحسينات التي تساعد على الإمساك الجيد. نرى أشياء مثل الأسطح الخشنة، والطلاءات اللاصقة غير القابلة للانزلاق، وأحياناً شرائط مطاطية صغيرة على الحواف تمنح تماسكاً أفضل. توضح البيانات الميدانية لماذا تعتبر هذه الميزات مهمة للغاية. أجرت دراسة معينة مراجعة لعدة مواقع بناء قام بعضها بتحديث أنظمة منع الانزلاق الخاصة بها. ما الذي تم اكتشافه؟ انخفاض بلغ حوالي 40 حادثاً متعلقاً بالانزلاق مقارنة بما كان عليه الوضع من قبل. هذا النوع من الانخفاض يظهر بوضوح مدى الفرق الذي يمكن أن تحدثه القدم السليمة في مجال سلامة العمال في مواقع العمل المختلفة.

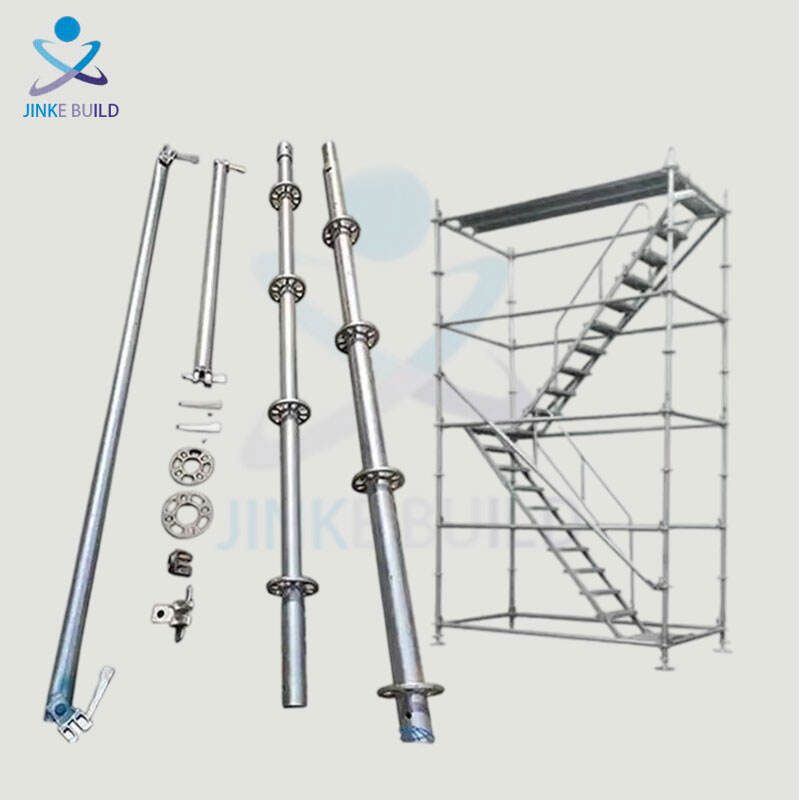

يعتمد عمال البناء في جميع أنحاء البلاد على منصة الدعم الفولاذية المتنقلة عالية الجودة لتلبية احتياجاتهم من الإطارات على شكل H لأنها تعمل بشكل موثوق في أكثر الأوقات حرجاً. إن الاستقرار والموثوقية ليست مجرد مصطلحات رنانة هنا، بل هي عوامل أمان حقيقية تضمن سلامة العمال أثناء العمل على الارتفاعات. ووفقاً للملاحظات الميدانية التي قدمها مفوّضو المواقع، فإن الطواقم تشير إلى تسارع وتيرة العمل نظراً لتمكنهم من الوصول إلى المستويات المختلفة دون الحاجة إلى تغيير السُلالم أو الخضوع لإجراءات تركيب معقدة. تظهر الميزة الحقيقية في المشاريع التي تتطلب نقل المعدات باستمرار بين الطوابق أو حول العقبات مثل الأنابيب والعتبات. يقدّر المقاولون متانة الإطار الفولاذي التي تبقى محفوظة حتى بعد أشهر من الاستخدام اليومي، كما يثمن أغلبهم حقيقة أن عملية التجميع تستغرق أقل من 30 دقيقة حتى بالنسبة لأعضاء الفريق الجدد. لا عجب إذن أن يُكثّف العديد من البنائين المهنيين من اقتنائهم لهذه الوحدات استعداداً لمشاريعهم الكبيرة المقبلة.

للساعين وراء وحدات ألواح متنقلة موثوقة ومتعددة الاستخدامات، هيكل حديدي محمول عالي الجودة للأعمال الإنشائية، إطار H لأرصفة البناء تقدم حلاً يتميز بالمتانة والمرونة لمهام البناء المختلفة.

يلعب الصلب المجلفن دوراً أساسياً في بناء سcaffolding (الهياكل المؤقتة) ذات الجودة العالية لأنه يدوم لفترة أطول ولا يصدأ بسهولة. عندما نتحدث عن هياكل مؤقتة تتحمل اختبار الزمن، فإن الصلب المجلفن هو ما يجعل ذلك ممكناً. هذا الأمر مهم جداً بالنسبة لمشاريع البناء، خصوصاً في الأماكن التي تكون فيها الظروف الجوية قاسية على المواد. فكّر في المناطق الساحلية حيث تؤدي رطوبة الهواء المالح إلى تآكل الصلب العادي بسرعة كبيرة. أنظمة القفل السريع في الهياكل المؤقتة الحديثة تُحدث تغييراً كاملاً. تسمح هذه الأنظمة للعمال بتركيب وتفكيك الهياكل المؤقتة بشكل أسرع بكثير من الطرق التقليدية. الفرق واضح في الموقع - لا تتأخر المشاريع انتظاراً لتركيب أو تفكيك الهياكل المؤقتة. التجميع الأسرع يعني جداول زمنية أفضل بشكل عام، وعندما تنتهي المهمة في الوقت المحدد، يوفّر الجميع المال على المدى الطويل.

إن استخدام الفولاذ المجلفن يُحدث فرقاً حقيقياً في قطاع البناء، وذلك لقدرته على التحمل لفترة أطول وعدم تآكله بسهولة بالصدأ. عندما يستخدم المقاولون هذه المواد في تركيب السقالات، فإنها توفر حماية من الأضرار الناتجة عن الظروف الجوية التي من شأنها أن تؤدي إلى تآكل الفولاذ العادي. هذا يعني أن المعدات تبقى قابلة للاستخدام لسنوات عديدة بدلاً من أشهر قليلة، مما يؤدي إلى توفير المال على المدى الطويل حيث لا تصبح الحاجة إلى الاستبدال متكررة. بالإضافة إلى ذلك، يضيف نظام القفل السريع طبقة إضافية من الراحة. يمكن للعمال تركيب السقالات وتفكيكها بسرعة أكبر مقارنة بالطرق التقليدية، ما يجعل هذه الميزة ضرورية للغاية في مواقع العمل الكبيرة حيث يُعد الوقت عاملاً مهماً في الإنجاز وعدم إهدار الساعات في أعمال التركيب.

في الوقت الحالي، تتحرك أعمال البناء بسرعة البرق، لذا فإن القدرة على تجميع وتفكيك السقالات بسرعة تُحدث فرقاً كبيراً في إنجاز الأعمال في الوقت المحدد. تشير الأبحاث التي أجرتها عدة شركات بناء إلى أن الانتقال إلى أنظمة سقالات محسّنة يمكن أن يقلل بالفعل من مدة تنفيذ المشاريع بنسبة تصل إلى 20%. عند العمل على مباني كبيرة مثل ناطحات السحاب أو مشاريع البنية التحتية الكبرى، حيث تكون المواعيد النهائية ضيقة والتغيرات الجوية شديدة ومتقلبة، تتميز سقالات الإطارات ذات الجودة العالية بأنها مصنوعة من فولاذ مغلفن على الساخن مقاوم للعوامل الجوية، مما يمنحها مقاومة للظروف القاسية. وتتناسب طبيعة النظام الوحدية بشكل خاص مع مشاريع البناء الضخمة أو مهام الصيانة في المناطق الصعبة مثل المناطق الساحلية أو المنشآت الصناعية، حيث قد تواجه الأنظمة التقليدية صعوبات في الأداء.

تتطلب الدفيئات أنواعًا خاصة من السقالات، وفي الوقت الحالي، بدأت التصاميم الوحدوية (المودولارية) تلعب دورًا كبيرًا في مواجهة هذا التحدي بفضل قابلتها للتكيف وكفاءتها العالية. بالنسبة لأي شخص يدير عمليات في دفيئة، تجعل السقالات الوحدوية الحياة أسهل كثيرًا لأنها قابلة للفك والتركيب مرة أخرى كلما تطلب الأمر ذلك. يمكن لهذه الهياكل التعامل مع مختلف الظروف داخل مساحة الدفيئة. إن المرونة تلعب دورًا كبيرًا هنا لأن الدفيئات ليست أماكن ثابتة على الإطلاق. تنمو النباتات لتصبح أطول مع مرور الوقت، تُضاف أقسام جديدة، وأحيانًا يلزم إعادة ترتيب التخطيط بالكامل عند تغير الفصول أو أنواع المحاصيل. هذا بالضبط سبب أهمية وجود سقالة تتكيف مع الظروف المتغيرة بدلًا من أن تنهار تحت الضغط، وهو أمر بالغ الأهمية للعمليات المستمرة.

تلعب قوائم التحقق من الفحوصات الدورية دوراً كبيراً في الحفاظ على سلامة هياكل الركائز مع مرور الوقت. تحتاج القوائم الجيدة إلى تغطية أمور مثل مدى صلابة الهيكل، وما إذا كانت جميع الأجزاء متصلة بشكل صحيح، وحالة الأسطح. يتفق معظم المختصين على أن فحص الركائز بانتظام ليس أمراً اختيارياً إذا أردنا الحفاظ على مستويات السلامة المناسبة. عادةً، يجب على العمال فحص الركائز قبل تركيبها للمرة الأولى، ثم مرة أخرى على فترات منتظمة بعد ذلك، بحيث يكون الفحص الشهري كافياً في معظم الحالات. تساعد هذه الفحوصات الدورية على اكتشاف أي تغييرات أو أضرار مبكراً قبل أن تتحول إلى مشكلات جدية. تشير البيانات من SafeWork NSW إلى أهمية هذا الأمر، حيث يعود سبب العديد من الحوادث المتعلقة بالركائز إلى عادات صيانة سيئة. لهذا السبب، فإن أخذ الوقت الكافي لإجراء فحوصات دقيقة يُحدث فرقاً كبيراً بين العمليات الآمنة والكوارث المحتملة.

تجعل سقالات مقاومة الطقس كل الفرق عندما يتعلق الأمر بالحماية من المطر والثلج وتلك الأشعة فوق البنفسجية الضارة. هناك عدة طرق للقيام هذا الحماية. يُعد تغطية السقالات بمواد مقاومة للماء فعّالاً إلى حدٍ ما، كما أن استخدام طلاء يتحمل الأضرار الناتجة عن الأشعة فوق البنفسجية يُعد مفيدًا جدًا في إطالة عمر السقالات. وعند اختيار المواد المناسبة للعمل، فإن استخدام تلك المصممة خصيصًا لتحمل الظروف الجوية القاسية يضيف طبقة حماية إضافية. ولقد شهدنا نتائج فعلية من هذه الأساليب، فعلى سبيل المثال، المواد المغلفنة تقاوم التآكل بشكل أفضل بكثير من الخيارات العادية، مما يعني أن السقالات تظل قوية وآمنة حتى بعد سنوات من التعرض للعوامل الجوية. عادةً ما يجد المقاولون الذين يستثمرون في عزل الطقس المناسب أن معداتهم تدوم لفترة أطول بكثير من أولئك الذين يتجاهلون هذه الخطوة المهمة.

تأتي أنظمة الرفوف الصغيرة بالعديد من المزايا، خاصة عند التعامل مع مشاريع البناء الصغيرة في المدينة. إن وزن هذه الوحدات الخفيف يجعلها أسهل في التنقل، كما يُحتاج إلى عدد أقل من العمال لتركيبها أو تفكيكها. يتم تقليل وقت الإعداد بشكل كبير، وهو أمر مهم للغاية في حالات التركيب المؤقتة حيث يعد كل دقيقة. ميزة أخرى كبيرة؟ يمكن للنماذج المدمجة الدخول إلى أماكن ضيقة للغاية مع الحفاظ على استقرار وسلامة جيدين، مما يجعلها مثالية لتلك المهام الصعبة في الزقاق الضيق أو الأماكن المزدحمة في المدينة. يذكر المقاولون الذين استخدموا هذه الأنظمة الأصغر حجمًا مدى متانتها المدهشة بالنظر إلى صغر حجمها. ويشير العديد منهم إلى تحقيق نتائج جيدة بنفس مستوى الأنظمة الأكبر دون المشقة المرتبطة بها. ولأي شخص يقوم بأعمال في المناطق الحضرية المكتظة أو الظروف المحدودة الأخرى، فإن الاستثمار في حل رفوف مدمج أمر منطقي من حيث السلامة والكفاءة.

توجد العديد من خيارات السقالات ذات الأسعار المعقولة والمصممة للأماكن الضيقة والتي تحافظ على سلامة العمال وتقدم نتائج جيدة. كما أن هناك العديد من الخيارات الميسرة مثل الإطارات القابلة للتعديل وأنظمة الأبراج المتنقلة المصممة خصيصًا للمشاريع الصغيرة ولكنها تتماشى مع جميع متطلبات السلامة. وبالنسبة للشركات الصغيرة التي تواجه مشكلات في السيولة المالية، فهناك بدائل تمويلية تستحق النظر أيضًا. حيث تساعد خطط الشراء بالتقسيط والصفقات الإيجارية المرنة في تقليل المصروفات الأولية، مما يمكّن الشركات من الحصول على معدات جيدة دون إحداث فجوة في حساباتها البنكية. وتشير البيانات الصناعية إلى أنه على الرغم من انخفاض تكلفتها الأولية، إلا أنها تميل إلى التحمل لفترة أطول والعمل بشكل أفضل على المدى الطويل، مما يجعلها في النهاية عمليات شراء ذكية. والآن أصبح لدى المقاولين العاملين في مشاريع صغيرة الطرق الواقعية لتوفير المعدات المناسبة بأنفسهم دون إحداث أعباء مالية كبيرة، وفي الوقت نفسه الحفاظ على سلامة جميع العاملين في الموقع طوال مدة العمل.

حقوق النشر © شركة تيانجين جينكي للتكنولوجيا المحدودة. جميع الحقوق محفوظة - سياسة الخصوصية-مدونة