The decision between wooden and steel scaffolding boards really matters when it comes to how a construction job turns out. Most contractors go for wood because it's cheaper and easier to work with. These boards are light enough that workers can carry them around all day, which is why many small jobs or temporary setups still rely on wood planks. But there's a catch wood tends to warp if left outside too long or rot when exposed to moisture, so regular inspections and occasional sanding become part of the routine maintenance. Steel boards tell a different story altogether. These bad boys last way longer and handle whatever weather throws at them without complaint. A steel plank won't crack under pressure from heavy materials either, which is why big commercial sites and infrastructure projects typically stick with steel. Sure, they cost more upfront, but nobody wants to replace boards every few months during rainy season.

Research indicates steel scaffold boards tend to outlast wooden ones significantly while needing far less upkeep over time. Sure, wood might be cheaper initially, but all those replacements and repairs add up fast when looking at total costs across multiple projects. Steel just doesn't break down like wood does either. These metal boards stand up better against rain, sun damage, and won't rot away no matter what kind of weather they face on site. Industry experts often point out that selecting between wood and steel really comes down to what works best for each particular job site. Contractors need to weigh initial spending versus long term savings, plus think about how much hassle each material brings along with it during construction.

Knowing what load capacity means makes all the difference when picking out scaffold boards for a job. Basically, load capacity tells us how much weight the scaffolding can actually hold before it starts to fail. Following those industry guidelines isn't just paperwork stuff either—it keeps everyone safe on site. When workers grab boards that don't meet the required load specs, accidents happen fast. We've seen cases where improper boards led to collapses during construction work, putting lives at risk and causing major delays. Take residential versus commercial buildings as an example. Most home improvement jobs need boards rated for around 25 psf (pounds per square foot), but big commercial sites often require something closer to 50 psf or even higher depending on what materials they're handling daily.

Different kinds of construction jobs need varying levels of structural support. When working on commercial sites, there's usually way more weight involved because of all the heavy machinery plus multiple workers moving around at once. That means we need stronger scaffolding setups for these projects. For homes though, most residential work only requires basic scaffolding since typical repairs or renovations don't involve such intense loads. Getting this wrong can lead to serious problems down the road. We've seen plenty of real world situations where improper load calculations resulted in collapsed structures, sometimes injuring people and definitely creating major headaches for companies dealing with lawsuits afterward. Contractors who take time to properly assess what their particular job needs in terms of both expected weight distribution and how many crew members will be accessing different areas tend to avoid these issues altogether while keeping operations running smoothly from day one.

Following OSHA's scaffolding rules makes all the difference when it comes to keeping workers safe on construction sites. The Occupational Safety and Health Administration has set down some pretty clear requirements for how scaffolding should be built and maintained, things like making sure it's installed correctly and getting checked regularly to avoid accidents. Weight distribution matters a lot too because if materials aren't spread out properly across the platform, there's a real risk of collapse. Construction firms that stick to these standards cut down on dangerous situations involving falls from heights and structural breakdowns, something most safety experts would back up without hesitation. Look at the numbers: places that enforce OSHA's guidelines have seen scaffolding accident rates drop by more than seventy percent compared to areas where these rules aren't followed consistently.

Anti slip features on scaffolding boards matter a lot because they help stop workers from getting hurt when they slip and fall. Most scaffolding comes with different types of grip enhancements these days. We see things like roughened surfaces, those sticky non skid coatings, and sometimes even little rubber strips along the edges that give better traction. Looking at actual field data makes it clear why these features are so important. One particular study looked at several construction sites where they had upgraded their anti slip systems. What did they find? About 40 fewer slip related incidents compared to before. That kind of drop shows just how much difference proper footing can make for worker safety on job sites everywhere.

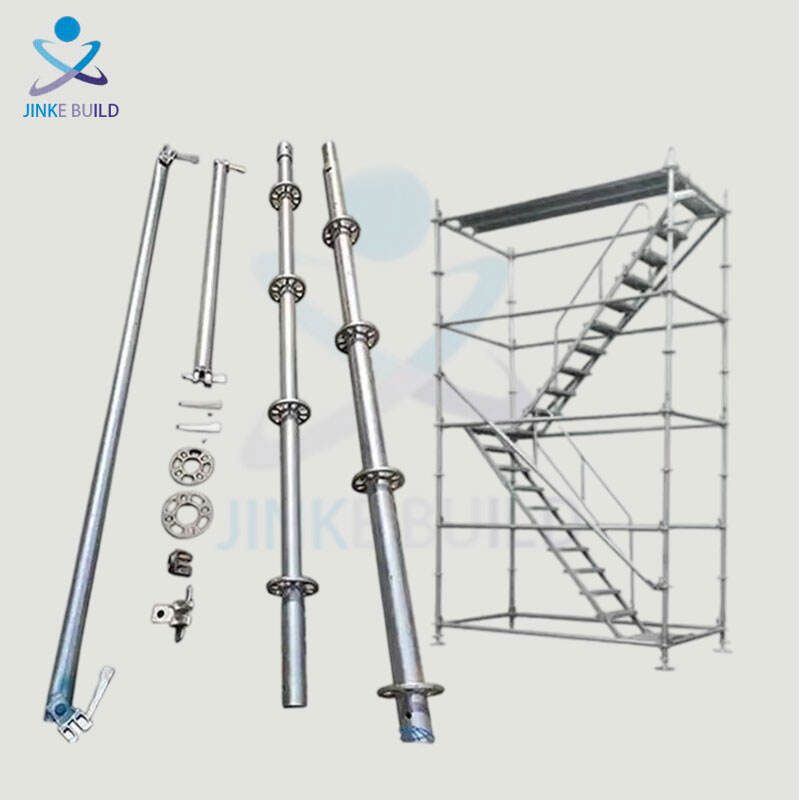

Construction workers across the country swear by the High Quality Mobile Steel Frame Scaffold for their H Frame needs because it just works when they need it most. Stability and reliability aren't just buzzwords here these are actual safety factors that keep workers secure at height while they get the job done. According to field observations from site managers, crews report faster work times since they can reach different levels without waiting for ladder changes or complex setup procedures. The real advantage shows up on jobs where equipment needs constant relocation between floors or around obstacles like pipes and beams. Contractors love how durable the steel frame remains after months of daily use, and most appreciate that assembly takes less than 30 minutes even for new team members. No wonder so many professional builders stockpile these units for their next big project.

For those seeking reliable and versatile mobile scaffolding units, the High Quality Mobile Steel Frame Scaffold for Construction H Frame Scaffolding offers a solution that's both durable and adaptable to various construction tasks.

Galvanized steel plays a key role in building good quality scaffolding because it lasts longer and doesn't rust easily. When we talk about scaffolding that stands the test of time, galvanized steel is what makes it happen. This matters a lot for construction jobs, particularly in places where weather can be tough on materials. Think about coastal regions where salt air and moisture combine to wear down regular steel pretty fast. Speed lock systems in modern scaffolding change things completely. These systems let workers put up and take down scaffolding much quicker than traditional methods. The difference is noticeable on site - projects don't get held up waiting for scaffolding to go up or come down. Faster assembly means better timelines overall, and when a job finishes on schedule, everyone saves money in the long run.

Galvanized steel really makes a difference in construction because it lasts longer and doesn't rust easily. When builders use these materials for scaffolding, they get protection from weather damage that would otherwise eat away at regular steel. This means the equipment stays usable for years instead of just months, saving money down the road when replacements aren't needed so often. The speed lock system adds another layer of convenience too. Workers can put up and take down scaffolding much faster than traditional methods allow. On big job sites where time equals money, this feature becomes absolutely essential for keeping projects on schedule without wasting hours on assembly work.

The construction business moves at lightning speed these days, so being able to put together and take apart scaffolding quickly makes all the difference when it comes to getting work done on schedule. Research from several construction firms indicates that switching to better scaffolding systems can actually cut down project timelines by around 20%. When working on big buildings like skyscrapers or major infrastructure projects where deadlines are tight and weather conditions vary wildly, the Quality Ladder Frame Scaffolding stands out because it's built with weatherproof hot dip galvanized steel that holds up against harsh elements. The system's modular nature works particularly well for massive construction jobs or maintenance tasks in tough spots such as seaside areas or industrial facilities where traditional setups might struggle.

Greenhouses require special kinds of scaffolding, and these days modular designs are really stepping up to meet that challenge thanks to how adaptable and efficient they tend to be. For anyone running a greenhouse operation, modular scaffolding makes life much easier since it can be taken apart and put back together again whenever needed. The structures can handle all sorts of different situations within the greenhouse space. Flexibility matters a lot here because greenhouses aren't static places at all. Plants grow taller over time, new sections get added, sometimes entire layouts need rearranging when seasons change or crop types switch around. That's exactly why having scaffolding that bends with the situation rather than breaking under pressure becomes so important for ongoing operations.

Checklists for routine inspections play a big role in keeping scaffolding structures safe over time. Good checklists need to cover things like how solid the structure is, whether all the parts are properly connected, and what condition the surfaces are in. Most professionals agree that checking scaffolding regularly isn't optional if we want to maintain proper safety levels. Usually, workers should inspect scaffolding right before putting it up for the first time, then again at regular intervals afterward something like once a month works well in most cases. These periodic checks catch changes or damage early before they become serious problems. Looking at data from SafeWork NSW shows why this matters so much many accidents involving scaffolding actually come down to poor maintenance habits. That's why taking the time for proper inspections makes all the difference between safe operations and potential disasters.

Weatherproofing scaffolding makes all the difference when it comes to protecting against rain, snow, and those damaging UV rays. There are several ways to go about this protection stuff. Covering up the scaffolding with materials that resist water works pretty well, and putting on some kind of coating that stands up to UV damage can really help extend how long the scaffolding lasts. When picking out materials for the job, going for ones made to handle tough weather conditions adds another layer of defense. We've seen real world results from these approaches too. Take galvanized materials for instance. They fight off corrosion much better than regular options, which means the scaffolding stays strong and safe even after years of exposure to the elements. Contractors who invest in proper weatherproofing typically find their equipment lasts far longer than those who skip this important step.

Small scaffolding systems come with plenty of perks, especially when dealing with minor construction jobs around town. The fact that these units weigh so little means they're much easier to move around, and fewer workers are needed to put them together or take them apart. Setup time gets cut down significantly, something that matters a lot for temporary installations where every minute counts. Another big plus? Compact models can squeeze into really tight spots while still maintaining solid stability and safety standards, making them perfect for those tricky renovation jobs in narrow alleyways or crowded city lots. Contractors who've used these smaller systems often mention how surprisingly sturdy they are considering their size. Many report getting just as good results as larger setups but without all the hassle. For anyone tackling work in dense urban areas or other cramped conditions, investing in a compact scaffolding solution just makes sense from both safety and efficiency standpoints.

There are plenty of budget friendly scaffolding choices for tight spaces that still keep workers safe and deliver good results. Many affordable options exist like adjustable frames and mobile tower systems designed specifically for smaller jobs but built to meet all safety requirements. For smaller contractors dealing with cash flow issues, there are financing alternatives worth considering too. Rent to own plans and flexible rental deals help cut down on immediate expenses so businesses can get their hands on decent equipment without draining their bank accounts first. Industry data shows that even though these options cost less initially, they tend to last longer and work better over time making them smart buys eventually. Contractors working on smaller scale projects now have realistic ways to equip themselves properly without breaking the bank while keeping everyone onsite safe throughout the job.

Copyright © Tianjin Jinke Technology Co., Ltd. All Rights Reserved - Privacy Policy - Blog